Decades of Steel, Unmatched Quality.

Risk Advantage Comparison

Compliance & Safety Assurance

Full compliance with National Food Safety Authority regulations, avoiding financial penalties.

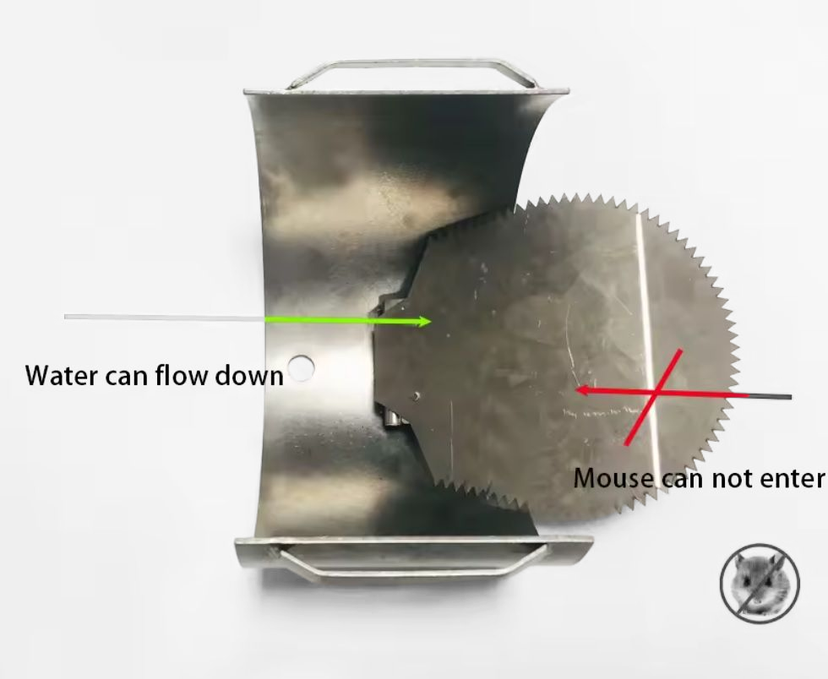

Zero Contamination Risk

Protected food supply with 99.9% reduction in contamination risk from sewage networks.

Business Continuity

Maintained operational licenses and facility status through proactive safety compliance.

Products

"Who We Are?"

Two Decades of Integrated Stainless Steel Manufacturing Solutions

At Maxwell Steel, we have over two decades of experience in the engineering industries, providing integrated solutions for manufacturing stainless steel products. We adhere to the highest standards of quality and safety by utilizing the latest global technologies and premium raw materials—304 (AISI 18/10) and 316 (AISI 18/10/2).

Our products serve various sectors, including food factories, healthcare facilities, hotels, restaurants, health clubs, and public establishments. We offer both standard and customized solutions that meet the unique needs of each client, all while maintaining the highest standards of quality and precision in manufacturing.

We take pride in keeping pace with global industrial developments while preserving our local identity, producing 100% Egyptian-made products that meet the needs of the domestic market and compete internationally. This is supported by a specialized technical team that provides continuous assistance.

Our Vision

To be the leader in the manufacture of safe drainage systems for food and industrial facilities made of stainless steel, through high-quality Egyptian products that achieve self-sufficiency and raise the status of "Made in Egypt" to global competition.

Our Mission

We design and manufacture integrated, environmentally friendly drainage network solutions using either 304 (AISI 18/10) or 316 (AISI 18/10/2) stainless steel, conforming to World Health Organization standards and Egyptian occupational health and safety standards. These solutions include underground drainage grates, water collection systems, and grease traps. We offer standard and customized solutions tailored to your facility's requirements, ensuring high quality and reliable performance for sustainable and efficient infrastructure.

Why Us

Why are stainless steel 304 (AISI 18/10) or stainless steel 316 (AISI 18/10/2) drainage solutions the ideal choice from ? Maxwell Steel

Corrosion & Rust Resistance

Uniquely resistant thanks to passivation, forming a protective chromium oxide layer that prevents oxidation and chemical reactions from moisture and harsh environments.

Superior Structural Durability

Exceptional hardness and tensile strength resist deformation and scratches. High shock absorption and load-bearing capacity ensure long-term stability and reliability.

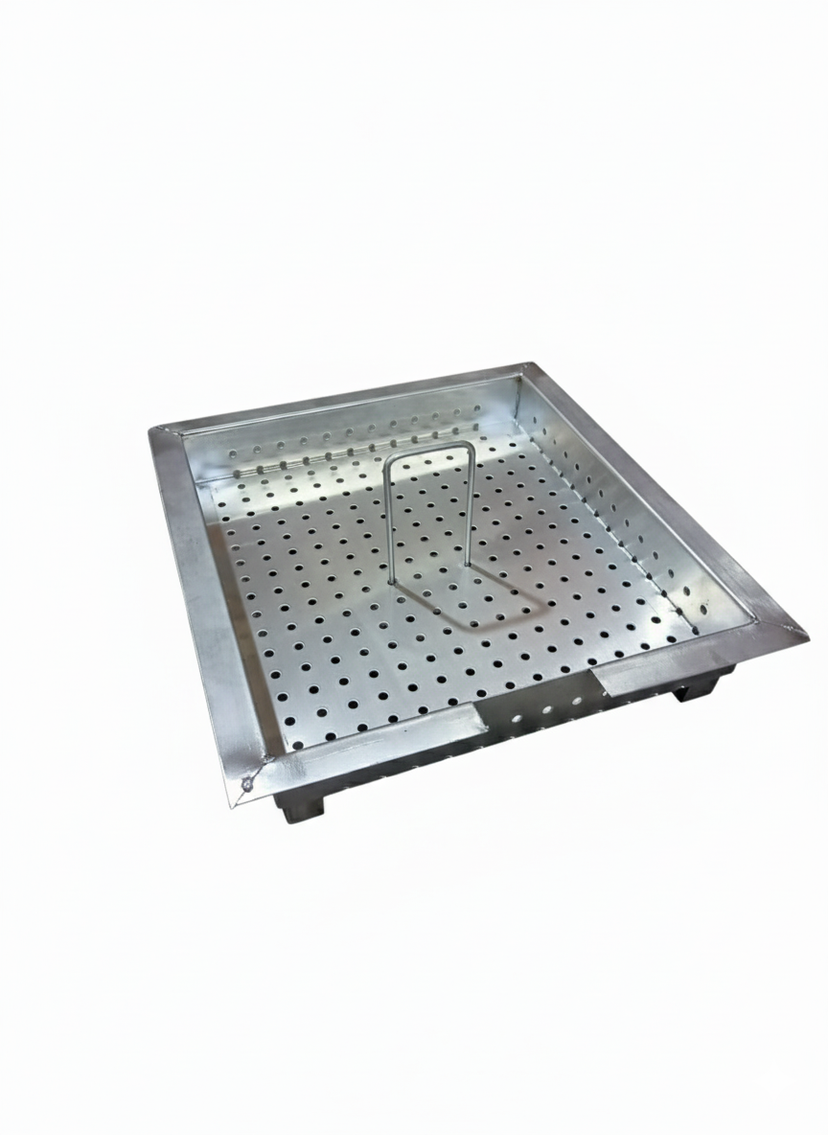

Easy Cleaning & Sterilization

Its smooth, non-porous surface naturally resists germs and impurities, allowing for fast, effective cleaning and high hygiene standards with minimal effort.

Professional & Sustainable Look

Adds a modern, elegant touch with a clean metallic lustre and uniform texture. Maintains its sparkling, sophisticated appearance without fading over time.

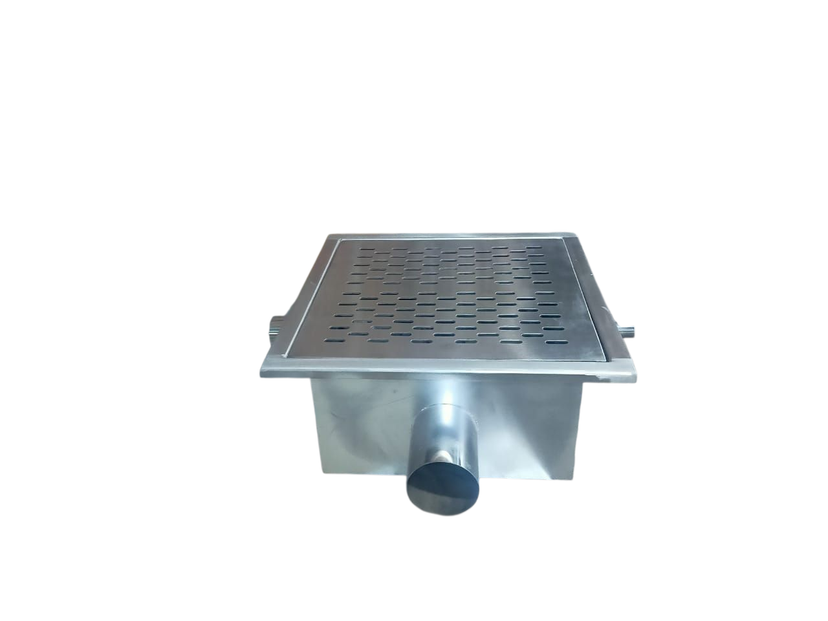

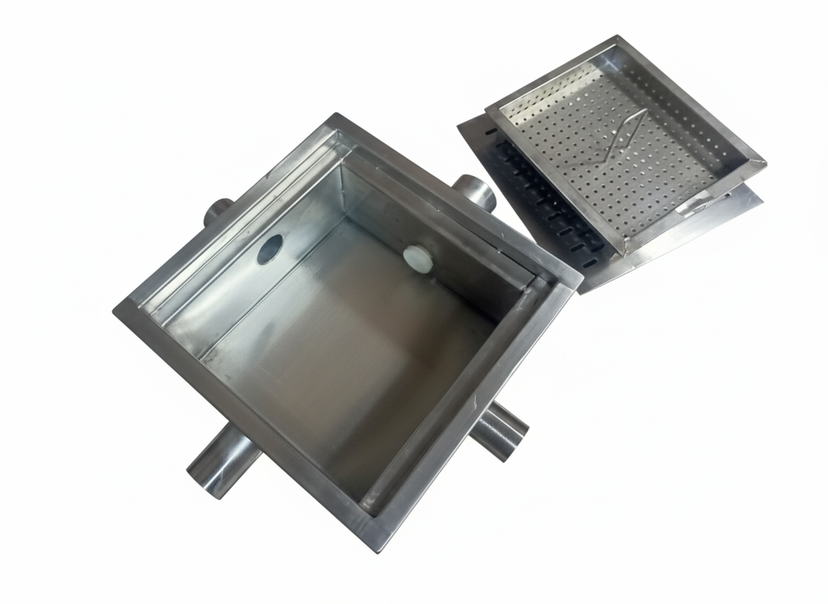

We produce integrated solutions for sanitation systems made of high-quality 304 or 316 stainless steel for the food industry. Maxwell Steel

Unwavering quality: Drainage solutions designed for maximum reliability

All our drainage products are made of stainless steel 304 (AISI 18/10) or 316 stainless steel (AISI 18/10/2) in accordance with World Health Organisation standards and Egyptian occupational health and safety standards, ensuring exceptional resistance to corrosion and chemicals. Our design ensures the highest standards of safety and ease of cleaning, while we offer standard and custom sizes to ensure perfect integration with any space, while maintaining a professional and elegant appearance.

Areas of application

Factories

Restaurants

Hospitals